Executive Summary

A customer desired independent control, simulation, and modeling of a leading vendor’s electric power switchgear for utility and on-site power generation during outages and utility power restoration. The company expected experts to collaborate and train their employees on the software to model, simulate, analyze, and safely protect critical business operations and infrastructure equipment during utility outages and seamlessly initiate operations when utility power is restored.

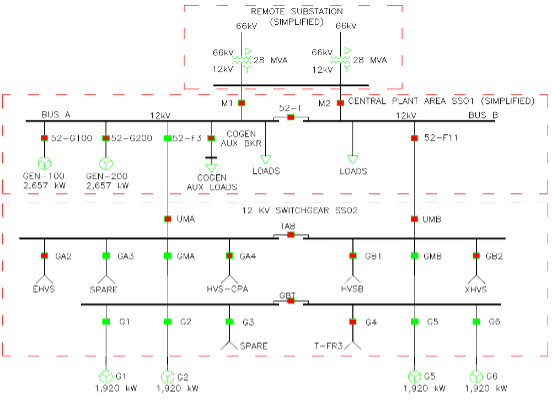

Background & Problem Information (See Appendix Diagram A)

This customer, as with other industrial sites, had critical electric loads subjected to power outages, which are very disruptive to business operations and critical equipment. Their electrical system consisted of two (2) switchgear lineups named SS01 and SS02. SS01 was the bus for normal loads, and SSO2 the bus for critical loads. The normal loads on SSO1 were connected to the utility through the two main utility breakers. The critical loads on the SS02 switchgear are also connected to the utility. During a utility outage SS02 is powered by four on-site diesel generators sized to support all loads on the critical SS02 bus and in some situations where utility power is lost, the system is allowed to feed diesel generator power from SS02 to SS01 to support vital loads during long-duration utility outages. SS01 has two generators connected for economic operations but they are not capable of maintaining critical loads through utility power losses due to mechanical limitations.

At industrial sites with critical loads the electrical switchgear supplier includes a control system to monitor, control and synchronize the generators with the utility service upon the loss and restoration of the utility power. This is an expensive proprietary system and typically not on the same control platform as used at the industrial site or integrated with the site’s HMI SCADA control room system. This requires higher maintenance and training costs and systems may not be flexible to allow more advanced and integrated applications.

This customer desired a Power System Operational and Control (PSOC) Simulator emulating their switchgear controls and HMI at a lower cost than the system provided by the switchgear manufacturer. They expected additional saving and benefits by collaborating and training employees on this new system implemented on the control platforms in use at their facility. The automation and facilities engineers would achieve mastery of the existing system as well as being empowered to visualize and test forward looking upgrades and improvements.

Methodology & Approach

Wunderlich-Malec (WM) power engineers are platform-independent control system integrators with experience working on switchgear and relays of all original equipment vendors. An in-depth analysis was made of the electric power distribution system, the equipment, customer loads and the existing control system platform. Upon review and in collaboration with the customer it was determined a simulator could be programmed to run on a PLC identical to the one used at the facility and with the same SCADA HMI software.

WM planned a separate PLC to generate simulated kW values for various points in the system. These kW values would be used to manage the system loads during the simulation process for system power loss and restoration with Load Management operation. The WM simulator would include the same protection relays as used onsite to simulate the system more accurately. The user interface for the simulator is provided at the HMI and custom control panel designed by WM to replicate hardware switches and breaker positions onsite.

Challenges & Limitations

The owner had significant challenges with the ability to train operators, missing documentation, and unpredictable outage response by the existing switchgear system. Due to the importance of the system and the challenges of receiving onsite support, self-sufficiency by the Owner’s personnel using the system was required. Reprogramming the existing system for integration and access to needed tools and training in the technology, functionality and operation of the system was not competitively available from the switchgear vendor.

Solution

The WM team created new documentation and the WM Simulator and Load Management software improved the existing system. Training now is simple as allocating personnel time with the simulator to assess common outage scenarios with HMI screen displays of the electrical distribution system and its responses.

WM provided complete design, programming, and assembly of a WM PSOC Simulator on a PLC identical to the one used at the facility and used the customers SCADA HMI software. A separate PLC is used to generate simulated kW values for various points in the system. These kW values are used to manage the system loads during the simulation process for system power loss and restoration. Load Management software uses the same protection relays used onsite to accurately simulate and when required control the power system.

When a Utility power loss is detected, the control system will execute steps to separate SS01 and SS02 and start the available diesel generators located on the SS02 bus. These generators are then synchronized onto the SS02 bus and become the power source for all loads on this bus and only critical loads on the SS01 bus. The addition of repowering SSO1 was validated by the PSOC and implemented in the field by WM.

Once the utility power source is restored and good voltage is detected, the control system begins the power restoration process by synchronizing SSO2 breakers. The generators come off-line when commanded and SSO2 is again on utility power.

Included in the system WM implemented its Load Management solution as an added function to the existing installation. This WM Load Management system provides priority-based and resource-managed Load Shed/Load Restoration functionality. This load management system works with hard wired Inputs/Outputs as well as IEC-61850 for high-speed tripping and restoration of system loads. In this specific installation, the system is designed to shed all designated non-critical loads upon a loss of Utility power. Relays from multiple vendors are supported within the WM Load Management framework.

WM provided several relays to highlight this ability to send IES-61850 commands to trip the breakers at a high speed, and to restore these loads once the system has detected the return of stable utility power.

Results

- The WM Simulator provides the owner independent capability to validate system control sequences for various load, tie and utility breaker configurations for their unique system configurations and applications.

- The owner is now able to pre-evaluate various failure and restoration processes to improve operational readiness, leading to better response times and higher operational reliability.

- The WM Load Management feature seamless transfer of critical loads to and from standby power and shut down and restore all non-critical loads.

- Owner employee training on the system has been simplified and more beneficial to employee and company.

Analysis

This WM Simulator with our Load Management solution has proven to be an asset for facilities on-site power generation during outages and utility power restoration. It can be implemented on any existing brown-field facility any number of ways, including (1) reprogramming the existing system, (2) modernizing the existing switchgear controllers and I/O, (3) moving to a new less costly controls platform, or (4) in some cases using a hybrid of the noted approaches.

Conclusion

The Wunderlich-Malec (WM) Power System Operational and Control Simulator (PSOC Simulator) was developed to simulate a well-known switchgear vendor’s proprietary based generator synchronizer and automatic power restoration control system commonly found at many facilities throughout the country.

- WM is an independent expert in engineering and methods used in power system operations and control.

- Familiar HMI SCADA screens simplify training employees on how the system operates during an outage, as well as how the system recovers when your utility power has been restored.

- The WM PSOC Simulator is allowing your operations team to run through and test different scenarios that may arise, enabling operators to evaluate these scenarios with the simulator and see how the system will react in a risk-free environment without affecting the real-world conditions.

- The simulator is a bridge step for visualizing and planning future upgrades, additions, or retrofits to a new platform.

- WM has the capability to unify the electrical controls onto a common platform with the plant controls, typically saving training, maintenance spare inventory costs, software costs, and reducing downtime and human error due to divergent systems.

The Wunderlich-Malec Power System Operational and Control (PSOC) Simulator is a worthy investment in the future reliability of your critical power system.

For More Information:

Contact Micah Houtz, Wunderlich-Malec Engineering:

603-686-3542 (cell)

Click here to jump to the top of this article.