Executive Summary:

This case study establishes the economic impacts of installing a Wunderlich-Malec Dispatchable Backup Power System for an Illinois cold storage facility facing high power costs and utility outages. This case study documents and reveals the following significant benefits:

- Reduce power costs by 44% (see Table 1) by dispatching backup power generation.

- Provide resilient backup power during utility grid outages.

- Provide modular site switchgear with spare breakers for future technologies (e.g. solar & storage).

- Option for uninterruptible power source (UPS) and 70% renewable power procurement.

Manufacturing Facility:

- Peak Demand: 2000 kW

- Annual Usage: 13200 MWh

Challenge

Commercial and Industrial facilities face serious power challenges:

- Power costs went up about 50% in five years and are still rising.

- Decreasing grid power reliability due to fires, storms, utility outages, brownouts, and system failures.

- Tier IV Diesel backup power issues: sunk cost, long lead times, limited run hours, and high emissions.

Over the past several years utility and PJM Independent System operator costs have risen dramatically. In Illinois, commercial costs recently jumped from about $80/MWH to over $128/MWH, driven by higher regulatory costs and an 8-fold increase in PJM ISO capacity charges. Commercial and Industrial facilities can expect prices to continue to increase due to restrictions on new fossil fueled power in Illinois and the expected large grid imbalance caused by intermittent power including solar PV and plug-in vehicles

Solution

WM developed a cleaner backup power solution that can be dispatched to maximize cost reduction, eliminate peak power costs, and enable access to lower-cost real-time power (Table 1). WM utilizes the next generation Caterpillar fast start full load acceptance natural gas gensets that perform like a diesel generator during a utility outage.

WM includes an option to add Uninterruptable Power or UPS to provide ride through capability as needed. This solution includes spare breakers to reduce the cost of adding solar PV and Battery Energy Storage Systems (BESS) as these technologies reduce cost and improve. A BESS system does not provide sufficient capacity to protect a facility during an extended outage nor can a BESS hedge an extended peak power event similar to the one-week Texas ice storm that resulted in prices over $1000/MWh for several days.

Table 1: Power Savings

Installing the WM Dispatchable Back-up Power Solution provides site generation that can be operated about 2000 hours per year which provides the following new capabilities for reliability lowering cost and hedging peak prices:

- Purchase low-cost real-time instead of retail power while dispatching backup generation to hedge peak prices.

- Dispatch to avoid PJM ISO capacity and transmission charges.

- Dispatch to avoid utility charges.

The subject cold storage facility utilizes 13200 MWh of power annually with a peak annual electric demand of 2000 kW. The Dispatchable Backup Power system will operate under the following conditions:

- During normal operation, the facility will be taking primary power from the utility and will remain connected to the utility unless the utility drops power. This includes purchasing on average 70% of the facilities’ annual power needs and generating ~30% locally through economic dispatch.

- During a loss of utility power, the site backup power will operate the facility in island mode.

- The site generation is operated in economic dispatch. In this mode, the system controller monitors power market and utility prices and dispatches generation to maximize savings:

- When real-time prices are higher than the cost to generate, generators are dispatched to hedge peak prices.

- Generation is dispatched to avoid PJM ISO capacity and transmission charges.

- Generation is dispatched to maximize utility power cost savings.

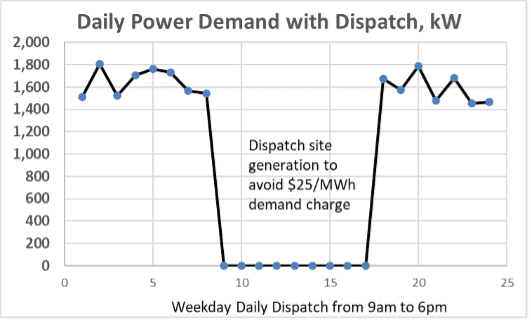

Figure 1: Weekday Daily Dispatch

System Features, Plans, and Renderings

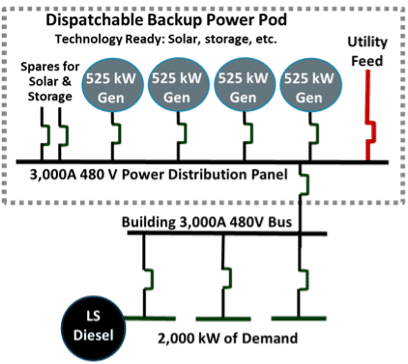

The Dispatchable Backup Power design features include the following key components. The microgrid layout and single line is shown in Figure 2. WM will deploy one 2100 kW module.

- Modular 480V Switchgear to integrate local generation, provide a parallel utility connection, and spare breakers for future technology integration such as solar PV and battery energy storage (BESS).

- 2100 kW Dispatchable Generation providing backup power for reliability/resiliency and dispatch of site generation to reduce power costs. The power system includes two (2) 3-way catalysts to achieve ultra-low emissions levels.

- WM mGrid® Site Power Controller to minimize costs and optimize operations & maintenance.

- Fiber Communications Network

- Runs on low pressure natural gas (2 psig) producing power for about $50/MWH.

Figure 2: Power System Single Line

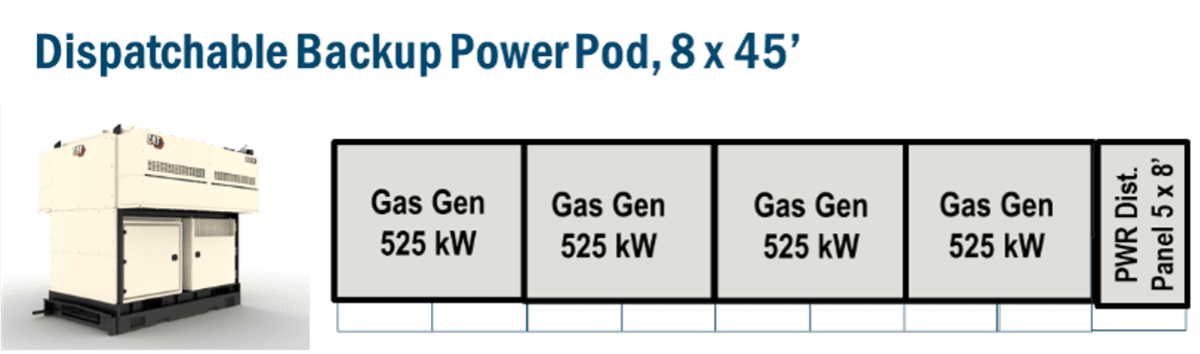

The 2,100 kW Dispatchable Power system includes eight independent containerized and packaged 525kW natural gas generator sets. Each container is equipped with black start capability and the ability to operate on its own or with any combination of generator sets. This provides for system redundancy and minimizes the impact of maintenance on operations. The system is also very compact requiring a footprint equal to a 50-foot ISO container (see Figure 3)

Figure 3: 2,100 kW Dispatchable Power System Layout and Space Requirements

Financial Performance & Emission Results

The facility currently pays approximately $128/MWh or $1,710,000 annually for electricity. These costs are expected to continue rising due to various factors including ISO capacity and transmission charges, which have increased eightfold in Illinois this year.

- Third-party retail power supply and ISO ancillary services (AS) charges

- PJM ISO capacity and transmission charges are rising dramatically in Illinois increasing by eight times this year.

- Utility demand, distribution, and state charges

Table 3: Power Costs & Savings

Installing dispatchable backup power generation enables facilities to reduce power costs and mitigate future price increases by:

- Zeroing out and eliminating capacity charges.

- Zeroing out and eliminating utility demand charges.

- Reducing retail power costs by up to 65%.

Wunderlich Malec evaluated the economic impact of installing a 2,100 kW Dispatchable Backup Power system. The system is built to WM design requirements leveraging six sigma risk assessments and experience from operations. WM also competitively bid on the major system components, achieving significant reductions in power costs. The system costs, estimated at $3,200,000, are shown in Table 4 and the system savings, estimated at $740,000, are shown in Table 5. This provides for a 4.2-year simple payback or 18% unlevered Internal Rate of Return (IRR).

Table 4: System Costs

This financial return is based upon no upfront capital from the customer. The sunk costs for customers already committed to installing backup power generation are about $1,500,000.

Table 5: Power Costs & Savings

We evaluated three financing options in Table 6:

- Case 1: Financing of the entire system cost

- Case 2: The customer provides $700,000.

- Case 3: The customer provides $1,500,000.

Table 6: Financing Options

EMISSIONS from these natural gas power systems will meet the most stringent US air quality requirements including those required by the CA South Coast Air Quality District.

Prepared by:

- John Kelly, WM Manager (john.kelly@wmeng.com)

- Reviewed by: Greg Rouse, WM Technical Specialist (greg.rouse@wmeng.com)

ATTACHMENT 1: PROJECT MODELING APPROACH

WM uses a proprietary 8760-hour software package, called MEA (Master Energy Analyzer), to model a wide array of site generation options (gas generation, solar, storage, etc.). The MEA tool uses 8760-hour energy analysis to determine the impact of site generation systems including energy cost savings, financial modeling, and emissions calculations. This includes the capability to model different operating and procurement strategies:

- Demand management and demand charge cost reduction.

- Various procurement options including utility power rates, retail power rates, ISO real-time power pool procurement, day-ahead power sales, and renewable energy credits.

- Real-time fuel switching based upon cost between electricity and natural gas.

- Renewable power procurement optimization includes strategies for up to 70 to 80% renewable power.

- Solar PV and storage sizing optimization

MEA is utilized to apply a wide array of economic dispatch rules, buffers, equipment efficiencies, and procurement options. Generator dispatch options include dispatching generation based on set hours of the day, electricity prices either from tiered rates or real time prices, peak shaving, or a combination of options. Basic thermal recovery modes include steam only, hot water only and chilled water modes.

MEA has operating restriction options to limit generator dispatch. These options include minimum generator output, minimum electric import, number of outage days per month, and technology start/stop limitations.

The results of the 8760-hour analysis include generator output, generator fuel consumption, supplemental electricity purchases. The data calculated in the 8760-hour analysis is then converted into monthly data for input into proforma and performance charting spreadsheets.

The proforma spreadsheet is an EXCEL template that has a tab for MEA to dump the monthly energy data. This includes monthly electric and gas consumption from the facility and generators as well as demand, operating hours, and other similar data. The spreadsheet uses this data to determine cost components including gas costs, electric costs, and maintenance costs. The template includes rate tables for electricity and gas tariffs. The spreadsheet has other tabs for summarizing results and has a tab for a combined 30-year income and cash flow statements which use the results from operation and project financing to determine paybacks and IRRs. For this analysis, unlevered IRR is utilized to evaluate financial performance.