Introduction

With the rising cost of power, power outages and environmental pressures, many commercial and industrial companies are turning to electrification for their buildings and campuses. While electrification helps companies achieve their net-zero carbon goals, it strains power distribution systems and increases power costs. This guide provides the steps for reducing and hedging power costs, building electric ready and resilient site power distribution, and accommodating competitive renewable energy.

Jump to:

- Sustainable Power Principles

- Create the Energy Sustainability Team and Plan Outline

- Detailed Steps to Guide Energy Sustainability Team

- Guide Authors

Sustainable energy experts developed four all-encompassing essentials that form the foundation for companies to achieve their sustainable power goals for their electrified facilities:

- Secure sponsorship of the corporate executive team, form a knowledgeable team, communicate benefits to stakeholders, and develop a corporate strategy.

- Install site generation, demand response, and fuel switching to protect the facility from price escalation, price spikes, and power outages or disruptions.

- Upgrade the site’s electric infrastructure to enable and support increases in electricity demand, integration of renewable power, and dramatic daily swings in power demand.

- Monitor and improve key performance indicators and perform continuous evaluation to ensure the project is on track and site activity is improving to meet the organization’s goals and objectives.

This brief guide is offered to help companies and their Sustainable Energy teams access competitive, renewable, and reliable power to serve these new electric buildings and campuses. It provides the key steps needed to achieve sustainable power goals and complements building and district energy sustainable energy and electrification plans (geothermal, heat pumps, solar PV, thermal storage, etc.).

Sustainable Power Principles

The following Principles rationalize the sometimes-competing objectives inherent in sustainable energy planning and offer perspective when applying the steps outlined in this guide.

- Carbon Reduction and Efficient Power – this is related to competitively procuring or generating on site lower carbon sources. However, users may be in a location with predominately coal fired generation or limited power procurement options. Utilizing 100% grid power may expose users to risks of utility power outages, price spikes, and higher prices.

- Reliability and Resiliency – as facilities electrify their uses and the bulk grid relies more heavily on intermittent renewable power, power interruptions and brownouts become a greater risk. Facilities should seek strategies to establish resilient site infrastructure and islanding capability while leveraging these assets to reduce costs.

- Cost Optimization and Operational Efficiency – as electricity prices become more volatile, facilities should explore and identify paths to manage power costs. This can include implementing strategies for hedging, creating energy models to simulate and evaluate future conditions to support the financial case for investment as well as continuous monitoring of facility efficiency and performance.

- Fuel Switching, Economic Dispatch and Grid Service – this is related to using onsite power generation and fuel switching to balance the electric distribution system and quickly respond to grid supply issues to minimize or offset carbon, lower costs, improve reliability, and generate revenue (e.g., demand response).

With these principles we can outline a methodology for implementation in the following section.

Create the Energy Sustainability Team and Plan Outline

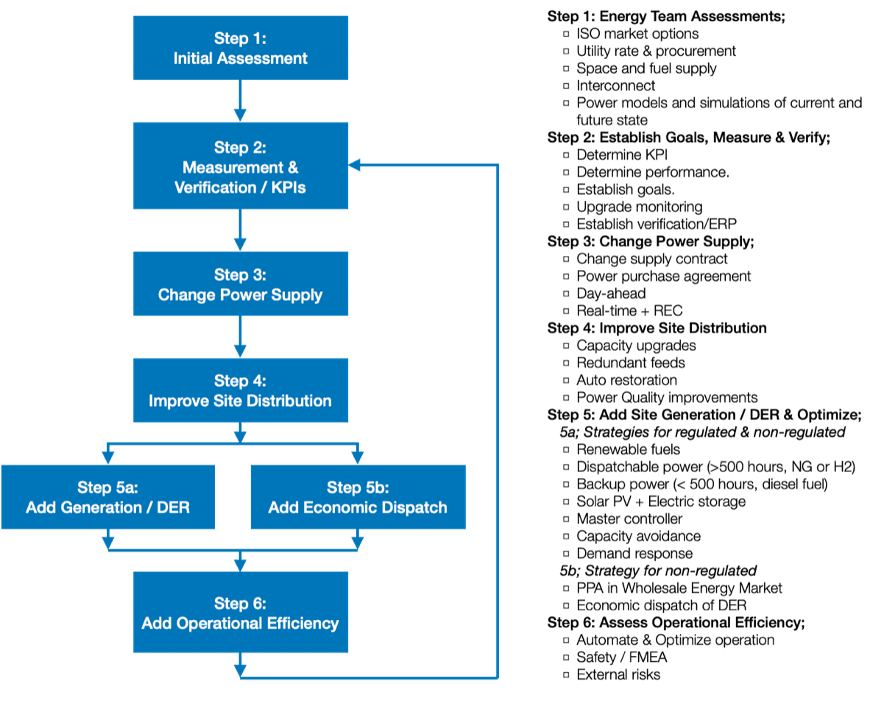

The team should consider the following steps as they proceed. Each site should assess and prioritize these steps based upon their site-specific needs and constraints (e.g., regulatory, space). For example, facilities and campuses may have limited authority to procure power (Step 3).

Step 1: Develop a team and perform a power assessment to evaluate the regulatory structure, rates, power models, and identify limitations and/or opportunities associated with their specific locations. This includes determining if skilled resources are available in-house to assess, plan, design and execute a sustainable power plan. Engaging third party resources provides value for tasks associated with information gathering, assessment, prioritizing these steps, planning, and implementation.

Step 2: Establish electricity performance metrics, goals, and measurement/verification program.

Step 3: Change power supply to reduce cost, lower carbon, and hedge price volatility and power outage risks.

Step 4: Upgrade site electrical distribution to increase capacity for electrification, provide resiliency, increase safety, improve power measurement, and reduce the cost for integration of local power sources.

Step 5a: Install site generation capable of supporting site operations in island mode when utility power is lost for resiliency and economic dispatch.

Step 5b: Install site power control automation to optimize economic dispatch of power generation capability, thermal/electric storage, and controllable loads.

Step 6: Establish operational efficiency and risk assessment. As appropriate automate operations, implement preventive maintenance programs, grid service programs, fuel switching, and other strategies designed to improve efficiency, eliminate cost and waste. This includes implementing a risk mitigation program.

These steps are further defined in the following section.

Detailed Steps to Guide Energy Sustainability Team

Strategic Overview

Firms that initiate a carbon reduction or net zero carbon emissions goals recognize the significant commitment of capital and resources. Key strategic questions to consider include:

- Is it possible to balance site loads with onsite generation and/or procure renewable power from the market?

- What options exist to replace fossil fueled power sources with non-carbon or at least lower carbon sources?

- What are the challenges or roadblocks? Are they permanent or will time provide new answers?

- How can the facilities develop a transition plan that includes all stakeholders?

Step 1: Develop Sustainable Energy Team and Perform an Assessment

To get started, identify an executive sponsor, appoint a team leader, and assign key employees to participate on the team. When considering team membership, keep in mind that operations, engineering, and finance are all stakeholders and contributors. However, the work may require subject matter experts from third-party partners to support the efforts. Each organization has employees with different skill sets and access to tools used in this work, however, few organizations have all that is needed.

The team should identify, select, and budget for the subject matter experts or vendors that can deliver on those tasks that in-house resources cannot. A guide for selecting subject matter experts or vendors is offered in Appendix A. A flow chart of plan steps and checklist for plan tasks is in Appendix B.

Step 2: Improve Energy Delivery Performance Metrics, Goals, and Verification

The second step is to establish a comprehensive yet focused set of relevant performance metrics, risk factors, and goals. These metrics are necessary to assess performance, identify gaps, and quantify the savings potential. Monthly energy bills provide basic usage and cost information. However, electric power supplies pose a significant risk and threat to facility operation (extended outages, massive price spikes, equipment damage, etc.). New industry standards, such as ISO-50001 and the Green Business Certification Inc.’s (GBCI) PEER program outline methods for defining metrics and processes for assessing electricity sustainability, performance, and risks.

The objective is to monitor key performance indicators, track performance, and identify new improvement strategies. Strategies include:

- Develop comprehensive set of performance metrics suitable for the location. As an example, refer to the GBCI PEER program resources (see peer.gbci.org/resources).

- Establish a means to measure ongoing performance against the current baseline. The difference is the value of improvement by the organization.

- Establish goals or upper limits of performance, the potential savings or value is the difference between the current condition and the upper limit of performance.

- Install metering to increase measurement quality and scope needed to verify progress.

- Implement facility/campus wide SCADA system to gather, store, trend, and report performance measures.

Step 3: Improve Power Supply Cost, Efficiency, and Carbon

This step can have the most significant impact on cost, carbon, and efficiency. Strategies include:

- Competitive bid for a new supplier with a lower carbon footprint and more efficient supply (e.g., wind, combined cycle)

- Contract for a Power Purchase Agreement for remote renewable power for a portion of the facility annual usage.

- Contract for a Power Purchase Agreement for local renewable power generation.

- Install cogeneration or tri-generation.

- Purchase retail or wholesale real-time power from the System Operator power pool leveraging site generation to hedge volatile real-time prices.

- Leverage proven software solutions to maximize savings and minimize carbon emissions.

- Purchase merchant wind and solar from the wholesale real-time power pool leveraging renewable energy credits.

- Transition cogeneration systems from baseload to real-time price dispatch.

Step 4: Upgrade the Site Electrical Distribution System

This step is critical to achieving net zero as the existing site distribution will not support integration of the technologies and new loads (e.g., electrification) stemming from the pursuit of net zero. Strategies include:

- Improve electrical system safety by providing actual real-time current and voltage data that can be utilized to improve the accuracy of arc-flash and power flow studies.

- Increase electrical system resiliency and reliability – Focus on the main power sources including the main buses from the utility and any current site generation capacity. Walk down all systems and focus on the key feeder systems to the facility. Inspect the main distribution and any emergency panel backed up by site generation to ensure they support the key life safety loads most critical production systems at the site. Consider the severity of system failure to key production systems.

- Reduce electricity system losses by installing higher efficiency transformers, increasing the voltage for distribution, and other innovative means.

- Increase electrical system capacity to accommodate switching from fossil fuels to electricity. This includes developing load models for projected future loads.

- Build islanding capability – changes to electrical system to enable reliable islanding using local generation. Be aware that just adding site generation is typically not sufficient to enable islanding. An expert assessment of the site loads and the control system should be included as well.

- Improve power measurement and quality.

- Install metering capable of measuring and recording all key power quality metrics.

- Install variable frequency drives on motors.

- Install power conditioning equipment.

- Analyze the utility’s main medium voltage feeder(s) for power quality during peak usage periods, including voltage sags, current imbalance, and other power quality issues. Site generation can be dispatched to stabilize site power quality.

Step 5a: Build Site Generation for Resiliency

Integrate sufficient generation to enable a facility to operate during a utility outage. Islanding capability can be developed in phases, with initial emphasis on generation and load response assets that provide a clear return on investment. Over time, islanding capability can expand to include more loads.

Islanding capability requires the deployment of a master controller to control load and balance demand and generation. Electrical system upgrades may be needed to ensure “black start” capability and to address power quality issues when in island mode.

Strategies to integrate generation to operate a facility as an island during a utility outage include:

- Modify site electrical systems to support integration of site generation islanding capability.

- Onsite generation is typically installed to provide backup of the main bus serving the facility critical production loads.

- Evaluate site generation with advanced hourly modeling to estimate the savings from various site generation options. Site generation can be used to avoid RSO coincident peak capacity charges and reduce host utility distribution charges. It can be deployed to improve facility power quality and provide full backup of the main bus serving the facility critical production loads.

- There may also be potential for added savings from generation heat recovery.

- Diesel backup is typically only utilized for backup due to air permit’s limits on run hours.

- Natural gas generation enables increased savings due to the ability to permit additional operating hours. Adding heat recovery will increase energy efficiency.

- Installing cogeneration or trigeneration which is the recovery of generation waste heat to produce heating and/or cooling.

- Install solar PV to improve carbon footprint.

- Consider biomass to leverage a renewable fuel.

- Install flywheels to stabilize power quality during grid connected and islanding modes.

- Be aware of other Distributed Energy Resources (DER) that may provide additional strategic or operational value.

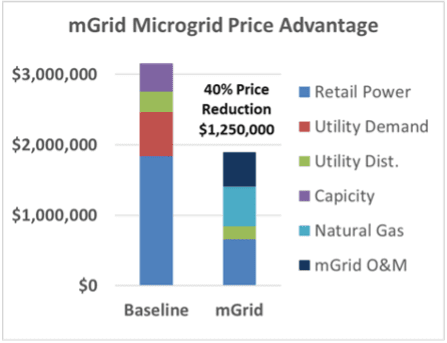

Step 5b: Add Economic Dispatch to Reduce Costs and Generate Revenue from Grid Service

This step addresses managing costs, generating revenue, and improving the efficiency of power peak demand usage. Peak power costs can exceed $1,000/MWh during periods of grid and supply constraints. In addition, several Regional System Operators (RSO) charge capacity charges based on the 5 days of highest peak use on the system in a year. Facilities can avoid RSO capacity and utility demand charges while also receiving payments for providing demand response services. Strategies include:

- Automated control of non-essential loads to reduce peak demand or respond to RSO and utility curtailment signals.

- Enable onsite generation to be dispatched to reduce system operator and utility charges. Switching from diesel backup to natural gas fueled backup increases dispatchable hours and opportunity for cost reduction. This is critical during major heat or cold waves that can cause power prices to spike for days or weeks, causing end user power prices to quickly increase.

Install islanding capability to maximize savings by adding automation control technology to:

- Pursue innovative procurement strategies, such as purchasing merchant real-time power at below retail power cost and hedged by site generation.

- Dispatch real-time generation to avoid utility, state, and system operator charges.

- Dispatch real-time generation to avoid peak power cost and create revenue by responding to utility and system operator demand response requests (i.e., grid service).

- Dispatch thermal or electric storage.

- Reduce controllable facility loads during demand response requests by the system operator.

This includes adding a system controller that optimizes power generation costs, price hedging, demand response, and reliability during grid connected or islanding modes (i.e., utility power lost).

Step 6: Implement Operational Efficiency and Risk Management Program

This step is designed to eliminate waste and risk. See WM Risk Assessment case study. Strategies include:

- Establish failure analysis program to track corrective action from failure root cause analysis.

- Perform a risk assessment leveraging six sigma or similar methods. This includes evaluating and addressing safety risks.

- Fuel switching from electric chillers to steam chillers, gas chillers, and/or thermal storage.

- Automate processes to reduce labor costs and errors.

- Review production processes to reduce the total energy consumed by measuring and trending power usage by area or process, to improve operational practices, or identify equipment degradation that may cause increased power usage.

- Use accurate measurement by submetering facility loads to evaluate electrical system capacity to accommodate new loads. Without this data, facility engineer’s conservative assumptions will lead to higher capital costs for electric system upgrades to support new loads.

- Analyze previous sustained power outage events, as well as momentary outages, to assess how production is disrupted and caused lost revenue.

- Track and review electrical equipment failures to determine root cause of failures and define corrective action. Poor power quality can damage electrical equipment and cause process system trips.

This Guide to Competitive Sustainable Power Authored By:

John Kelly, PE, BSEE

email: john.kelly@wmeng.com

- Co-developer of the GBCI PEER program resources

- registered six sigma green belt

- Patent for mGrid®

- Certificate in Environmental Engineering, Illinois Institute of Technology

- Certificate in Electricity Restructuring, Illinois Institute of Technology

- Chairman of the Board for non-profit LEAN – Local Energy Aggregation Networks

Greg Rouse, PE, MBA, BSME

email: greg.rouse@wmeng.com

- Co-developer of the GBCI PEER program resources

- registered six sigma green belt,

- Holder of 5 Patents

Tim Grigg, PE, MSME, MBA

email: tim.grigg@wmeng.com

Mark Cosentino, BSEE

email: mark.cosentino@wmeng.com

APPENDIX A:

Resources Needed to Develop and Implement Sustainable Energy Plan

Your selected team members should have the following skill sets and where lacking select industry specialists as consultants to complement your in-house capabilities. The team with support consultants should include:

- Expert knowledge in power distribution, energy reliability and efficiency designs and benefits alternative energy solutions.

- Proven experience in the design and delivery of electrical energy systems.

- Access to software and tools that can provide analysis and monitoring of energy supplies and distribution. Tools and knowledge to optimize your sustainable energy systems while maximizing savings to improve investment returns.

- Owner’s engineer to optimize a design plan and assist with a competitive implementation process.

- They should be experienced in the application of the worldwide microgrid standard (PEER).

To ensure seamless project execution they should be experienced in collaborating with existing customers, consultants, suppliers, and designers.

APPENDIX B:

Sustainability Guide Flow Chart & Checklist